Our legacy goes way beyond the cars and trucks that we make. For 120 years, we've used our values, scale and entrepreneurial spirit to build a better world.

Today the world around us is changing, and Ford+ is our plan to win. The Ford Operating System (Ford OS) will drive the rigor. discipline, clarity and behavior change we need to accelerate growth and unleash innovation.

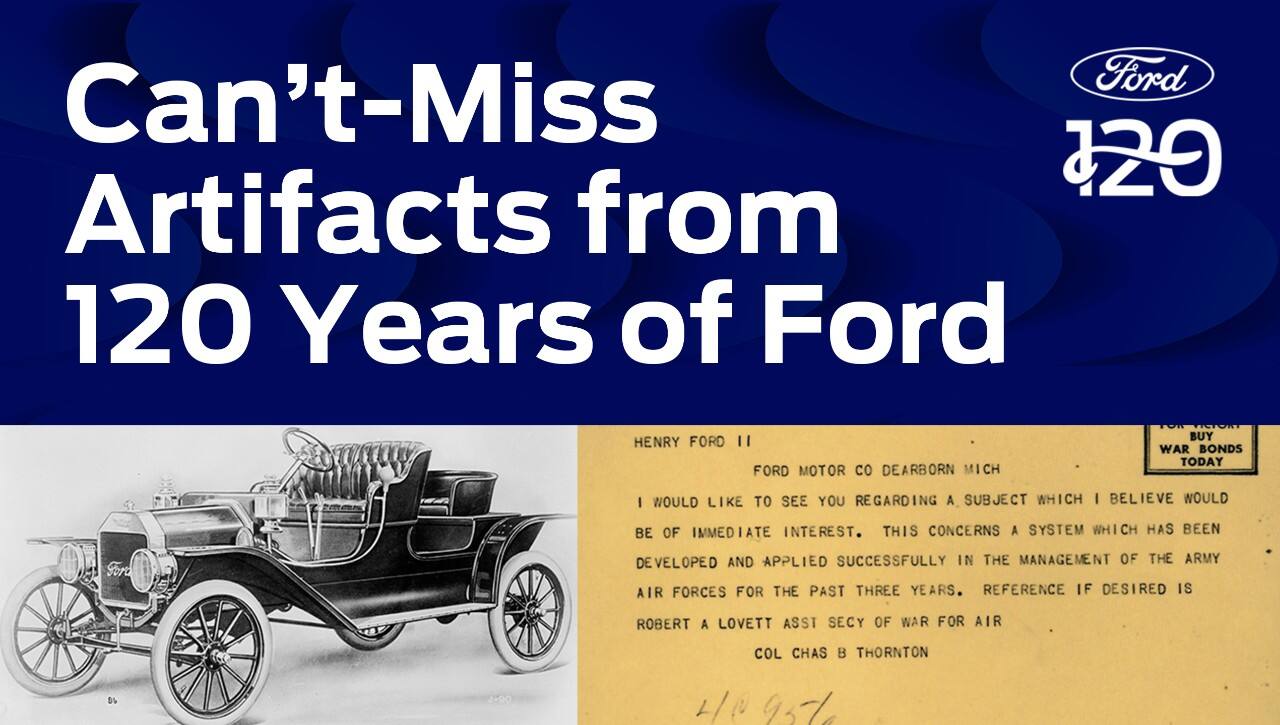

Our behaviors of Excellence, Focus and Collaboration define what Ford looks like when we're at our best. This virtual exhibit - curated by the Archives team - reinforces how these behaviors are core to our DNA.

- If Henry Ford didn’t have a mindset of Excellence, he may not have innovated and problem solved through two failed business attempts to create the Ford Motor Company in the first place.

- If Edsel Ford didn’t challenge us to Focus on the customer and their needs, then we may have been known as a one-hit-wonder. Instead, we shifted away from the Model T to build the Model A – and it saved our company.

- If the Whiz Kids didn’t Collaborate to implement changes to our business model, then our antiquated business practices may have led to our demise instead of supporting the creation of new systems – ones which resulted in breakthroughs like the Mustang.

Scroll through these three key turning point moments in our history to learn more about how lessons from our past can help propel our future.